I am happy to announce in this weeks post about the Captain America ball chair project that I finally have completed installation of all six wedges into the interior of the chair. YEA!

Here's a good shot of the project with all of the internal wedge shaped pieces finally in place. A lot of time and effort went into getting the right gaps between the wedges correct so hopefully my work will be done with this portion of the project. Lots of cutting, measuring, glassing and fitting over and over until I was happy with everything. I am more than happy to move on to some other portion of the project that will be a lot more fun.

In this photo of the interior I started placing paper templates to figure out where I want the lights, light switches, speakers and air vent nozzles to be places. It was simpler to do this once the wedges had been mounted so that I could sit in the chair and get an idea as to where I want everything to be placed in this portion of the build.

Most everything is mounted in the top three wedges that you see in the photo above. Starting with the left most wedge will be one speaker (large circle) and one air vent nozzle (small circle). In the center wedge will be mounted the three lights for reading or watching videos if I need more light. I originally was going to also put the controls for these lights in the center but found out that when sitting in the chair the switches would have been right over my head. Not a good idea. So the switch panel was moved to the wedge on the right along with the another speaker and another air nozzle.

As I pulled out the wedges that will have all of the speakers, lights and whatever, the mounts for these wedges now can be seen in the photos above. The little spool like mounts have an internal threaded rod connector mounted in them so mounting or dismounting the wedges makes the process an easy one. That's where all of the work to get the wedges spaced and assembled correctly pays off.

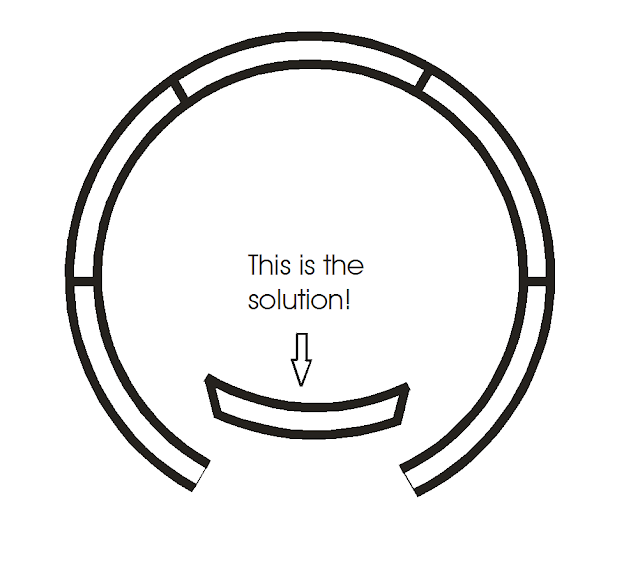

The first wedge that I started to modify for the accessories I have planned was the center one I spoke of earlier that will hold the lights for the chair. Here I have the center hole and three drilled holes for each of the lights that will be mounted marked for cutting on the fiber glass.

I drilled all of the smaller 1/4" holes with my hand drill and then drilled a pilot hole so I could cut out the larger holes. The first light mounted easily first time out.

Here all three lights have been mounted with very little fuss to get them in and spaced evenly. Nice to see things come together and progress being made in short order. These lights will really stand out once I get the wedges padded and covered with material to finish off the interior of the chair. I really like the look of the finished red mounts.

Next I took the housing for the speakers amplifier and marked out where I wanted to make the cut so this could be mounted. The simplest way I thought to do this is shown in the photo above. A little painters tape for starters to lay down a perimeter.

I removed the amplifier cover and taped the original marked square again only making it a half inch smaller all the way around. With this being done I then would have a lip that the housing would mate up against and not have a chance of a void if I cut it a little off.

I took my handy 1/4" drill bit and made holes at each corner and then cut along the tape from hole to hole using my Sonic Crafter vibrating cutter. A great tool by the way which made short work of this portion of the build. I held the housing over the opening to get an idea how the cavity would look with the housing in place.

So with the opening cut out of the wedge for the amplifier housing I set to work today to get the mounts for the housing squared away. This was just a matter of printing up mounting blocks that are mounted to both inner sides of the housing.

Across the back of the housing are two 3D printed bars that will hold the housing in place using 6mm button head capscrews.

Here is the housing in place mounted to the wedge with only one of the 3D printed bars just to show you how it all goes together. The bars and the blocks have a gap between them so when I tighten down the capscrews the housing is pulled tight against the inner surface of the wedge and the bar presses against the sandwiched wedge surfaces of the opening. Simple and it works great.

Here is how the housing looks when it would be mounted inside the chair. The match up of the edges of the housing and the inner surface of the wedge are as perfect as I can get them so I am pleased with my efforts once again. This assembly once it has been fully painted and mounted in the chair will be a very nice detail with the Captain America shield badge on the face of the housing. The housing will be painted Navy blue so it should be pretty impressive when it is completed.

In the next few days I'll work on getting the speakers and ventilation system mounted. This I have to be careful with as I have to make sure I get everything spaced right and figure out the wiring layout within the chair as well. Should not be a big problem that I can see. Just will have to take my time with it. Should be as much fun as these last couple of days have been placing the first few components. Total hours on the project now has risen to 362 hours. A lot of work and a lot of fun too. More to follow as I move forward.